Total

AQUAPHOR ULTRA series

Series of fully automatic ultrafiltration systems for mechanical water purification. Systems cuts off any visible sediment and impurities - turbidity, colloidal iron, organic macromolecules, bacteria, viruses and other impurities up to 0.005 microns.

Filtration rate - from 800 l/h to 3.200 l/h

.

Filtration rate - from 800 l/h to 3.200 l/h

.

Price on request

Add to compare

Ultrafiltration systems provides high degree of water purification from any visible sediment, mechanical particles and impurities up to 0.005 microns. System based on economical, environmentally-friendly and effective technology for water purification from submicron mechanical impurities, while the salt composition of the water doesn't change.

Hollow fiber membranes of the Aquaphor Ultra system implement the “Dead-end” ultrafiltration method (dead-end filtration) - filtration process through fibers alternates with direct or reverse flushing, which significantly reduces water consumption. In this case, water is filtered perpendicular to the surface of the hollow fibers, which reduces the likelihood of their clogging.

Ultrafiltration technology provides barrier against microbes and suspended particles to produce clean drinking water. Ultrafiltration also used in pre-treatment of open source water, sea water, and biologically treated water before RO systems and other membrane water purifiers.

Hollow fiber membranes of the Aquaphor Ultra system implement the “Dead-end” ultrafiltration method (dead-end filtration) - filtration process through fibers alternates with direct or reverse flushing, which significantly reduces water consumption. In this case, water is filtered perpendicular to the surface of the hollow fibers, which reduces the likelihood of their clogging.

Ultrafiltration technology provides barrier against microbes and suspended particles to produce clean drinking water. Ultrafiltration also used in pre-treatment of open source water, sea water, and biologically treated water before RO systems and other membrane water purifiers.

|

ULTRA 0.8 | ULTRA 1.6 | ULTRA 2.4 | ULTRA 3.2 |

|---|---|---|---|---|

| Filtration rate l/h |

800 | 1600 | 2400 | 3200 |

| Estimated productivity m3/h | 0.5-0.6 | 0.6-1.0 | 0.9-1.5 | 1.2-2.0 |

| Membrane area m2 |

5 | 10 | 15 | 20 |

| Membranes size | 90*1000 | 90*1000 | 90*1000 | 90*1000 |

| Membranes pore size | 0.01 | 0.01 | 0.01 | 0.01 |

| Dimensions cm |

1300 × 430 × 410 | 1300 × 430 × 410 | 1300 × 430 × 410 | 1300 × 430 × 410 |

| Weight kg |

8 | 12 | 25 | 31 |

| Connection size | G 3/4” | G 3/4” | G 3/4” | G 3/4” |

| Power supply | 220,12 | 220,12 | 220,12 |

High-quality filter element - Polysulfon, made from hollow fibers are made, has increased mechanical strength and inertness. This ensures a long service life and the possibility of effective service flushing. Intensive backwashing with clean water significantly increases efficiency of system cleaning.

Presence of pressure sensors and flow meter for consumed water allows the controller to collect real data on operation of system, conducting regeneration cycles on time, even when the parameters of the source water and the intensity of its consumption change. Without pressure sensors, automatic backwashing is impossible, since there is risk of destruction of hollow fibers.

Intelligent control system monitors and adjusts the interval between flushes, the so-called filter cycle, automatically. Built-in battery supports operation of internal clock for 24 hours when power supply disconnected. Flexible interface of controller allows make many settings and select a convenient operating mode for system depending on wishes. The main operating parameters of system displayed on the indicator panel: flow rate and pressure drop. Non-volatile memory allows controller to "remember" all settings and state of system at time of power outage.

Use of low-precision ball valves with servo drive ensures reliability and eliminates possibility of electric shock. System design allows basic system to be expanded from 2 to 4 modules, without additional cuts into the water supply, using the existing elements. This allows, if necessary, to increase productivity without resorting to significant investments.

Device

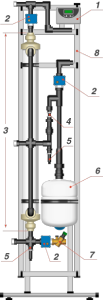

1. Ultra series controller with intelligent UV module performance monitoring system

2. Stainless steel ball valves with low-precision servo drive

3. UV module with hollow fibers made of polysulfone (PS)

4. Pulse liter counter for flow rate and filtration rate monitoring

5. Pressure sensors for monitoring pressure drops in operating mode and in backwash mode

6. Hydraulic tank for ensuring effective backwash with clean water

7. Pressure reducer combined with mesh filter for ensuring operating parameters of UV module (depending on model)

8. Frame part of UV system

1. Ultra series controller with intelligent UV module performance monitoring system

2. Stainless steel ball valves with low-precision servo drive

3. UV module with hollow fibers made of polysulfone (PS)

4. Pulse liter counter for flow rate and filtration rate monitoring

5. Pressure sensors for monitoring pressure drops in operating mode and in backwash mode

6. Hydraulic tank for ensuring effective backwash with clean water

7. Pressure reducer combined with mesh filter for ensuring operating parameters of UV module (depending on model)

8. Frame part of UV system